BIOFILTRATION: how to get rid of Nitrate and Ammonium contamination in ground waters

Ammonia is difficult to remove from water.

- DATE:

04/02/2018 - CATEGORY:

Article - LANGUAGE:

EN

“Lot has been written and rigorously explained about Reverse Osmosis and its principles: the aim of this short writing is to gather and share our experiences in a very simplified way, so that the patient reader could easily understand and find it, hopefully, interesting and useful”

In both Civil and Industrial applications Reverse Osmosis desalination (briefly R.O) is one of the most investigated and known membrane separation technologies, recognized for its capacity to produce high-quality water from a wide variety of water sources.

It has been found that the quality of permeate could be further improved by as simple as innovative on-board pipe re-routing: this new configuration, exploiting a fraction of permeate produced, is able to lower both the energy consumption and the overall TDS in the final permeate produced. We refer to this configuration with the name of Split partial Single-Pass and Split partial Second Pass R.O., both referred to as SSP-RO.

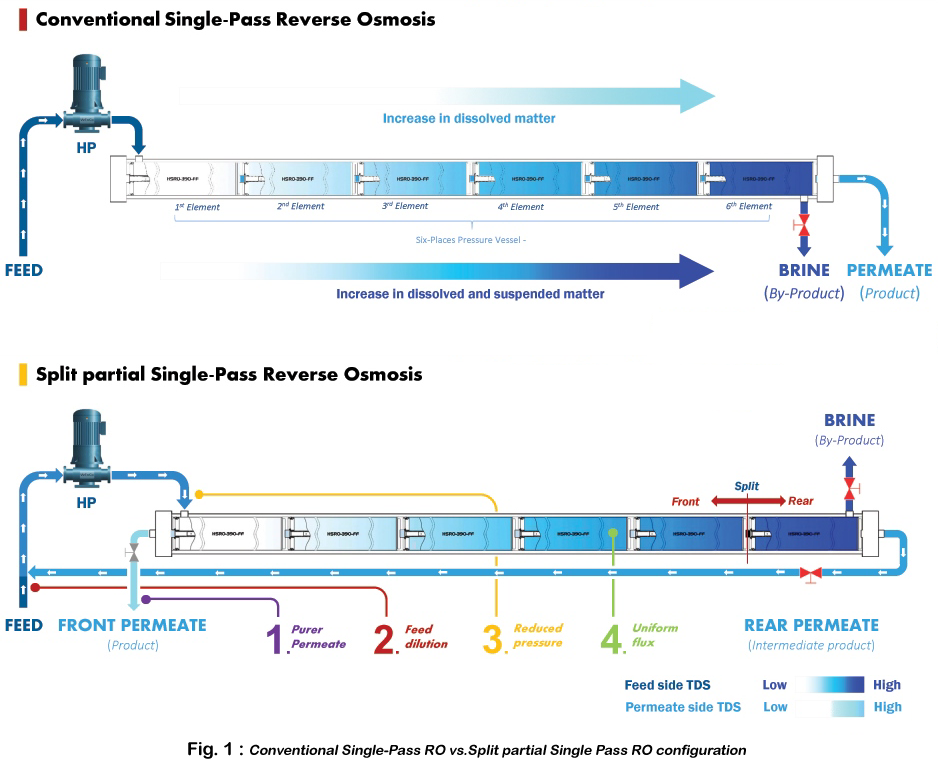

In single-pass R.O., the SSP-RO configuration is a design in which the permeate from the rear R.O. element in pressure vessel is looped back and blended with the R.O. feed, while the final permeate is extracted from the front R.O. element. This blending results in the dilution of the feed, leading to the production of higher-quality permeate with lower energy demand. This principle is based on the fact that front elements always produce better quality permeate than the elements at the back end of the vessel. In the image below the Conventional Single-Pass R.O. Vs the Split partial Single-Pass R.O. configurations:

In typical Brackish Water R.O. (BWRO) operating conditions, the SSP-RO design can produce an approximately 20% purer permeate compared to conventional single-pass R.O, with 90% of its specific energy requirement (kWh/mc).

“This principle is based on the fact that front elements always produce better quality permeate than the elements at the back end of the vessel”

These findings proved particularly useful in the refurbishment of existing Single-Pass R.O. units, to improve the overall perfomances with reduced investment.

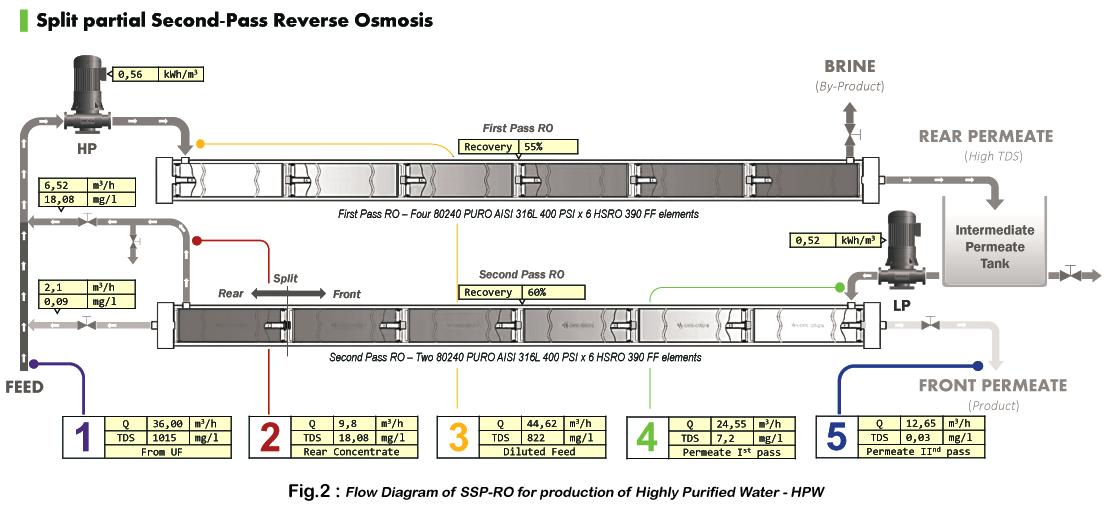

In multiple-pass R.O., such as in the production of High Purity Water or in applications with Seawater, the SSP-RO configuration proved its innovative strength with unparalleled advantages. The operating principle remains the same as for the Single-Pass but it is the product from the last pass - either permeate or concentrate, or both - who is looped and blended with feed, for higher water recovery and better permeate quality.

High Purity Water is made necessary in many industrial processes: it may be needed as-is or just as intermediate product before a final polishing stage. In both cases, it has been found that with innovative Split partial Second Pass R.O. design (still SSP-RO), the produced permeate quality could reach acceptable values for most applications, at very affordable specific cost.

Last November 2018 Water Engineers & Consultants – WEnCo entered in Service agreement with a Pharmaceutical Company in the Persian Gulf (read more here).

A peek inside the contract: along with Repairing and Maintenance Services, the Scope of Supply also included a Reverse Osmosis Unit to be made available and operative at site for the whole duration of maintenance Services, whose start is planned for January 2019.

Bottleneck: the short timetable. Not enough time to manufacture or rent and deliver a new R.O. unit by January 2019, at least none suitable for this service.

Our way-out: re-adaptation of an existing unit. For this purpose we selected an existing unit we already had in our warehouse, traded-in years ago as a balance of another contract. Manufactured in year 2000 as 6x6 single-stage and single-pass BWRO and entirely made of AISI 316/304L stainless steel, this unit was designed and built for well water with TDS of 600 mg/l, to produce 30 m³/h permeate with TDS of 20 mg/l. As to comply with new guarantees given "R.O. unit to produce 10 m³/h (± 10%) permeate with TDS of 2 mg/l (±10%) from filtered water with TDS of 1015 mg/l as per attached analysis...", we had time for just minimal, selected mods in the available timeframe.

A second pass was created from the existing onboard CIP section and the loop for the Split partial Second Pass was added. No skid modification was required, no multistage pumps replacement, no change in installed power. Just SW adaption was implemented. Thirty-six new, more efficient, 6” Heat Sanitizable elements were chosen for this application and all-new PTFE gaskets. In the image below the ultimate configuration given to the unit

The discovery: permeate quality exceeding expectations. Despite the few changes, we easily got 12,65 m³/h front permeate with TDS of 0,03 mg/l and 2,1 m³/h rear permeate with TDS of 0,09 mg/l. In just 30 days a newly refurbished unit was made available for IPS.

Conclusions: The SSP-RO design represents a cost-effective option to ugrade existing R.O. systems. Minimizing the size of the second-pass, in multi-pass configurations SSP-RO also allows substantial savings in capital investment and operating cost.

Thanks for the interest.

Ammonia is difficult to remove from water.

Treatment of industrial wastewater by microbial degradation is one of the most important waste management processes.